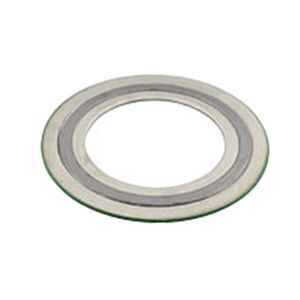

316 SS Spiral Wound FG, 316 SS IR, 316 SS OR

316 SS Spiral Wound FG, 316 SS IR, 316 SS OR

Manufacturers:

Spiral wound gaskets listed below consist of a 316 stainless steel inner ring, 316 windings with flexible graphite filler, and a 316 outer ring. Spiral wound gaskets are metallic gaskets consisting of an outer centering ring (also known as OCR, OR, or an outer guide ring), metallic windings with a soft filler material, and a solid inner ring, or any combination of the three. These gaskets are manufactured to meet specifications as outlined in ASME B16.20 (previously covered by API 601). Spiral-wound gaskets can handle more harsh and varied operating conditions than non-asbestos sheet gaskets in general. They are available in multiple materials and configurations.

Products

Color Codes

Spiral wound gaskets shall be marked with a color code that identifies the windings and filler materials. A continuous color around the outer edge of the centering ring shall identify the winding metal. The color identifying the filler material for NPS 1 1/2 and larger shall have four intermittent stripes spaced approximately 90 deg apart on the outer edge of the centering ring. Smaller size gaskets shall have a minimum of two stripes 180 deg apart. The colors shall conform to those listed in the table below.

| Per ASME B16.20-2007 | |

| Metallic Winding Materials | OD Color Code |

| Carbon Steel | Silver |

| 304 Stainless Steel | Yellow |

| 316L Stainless Steel | Green |

| 317L Stainless Steel | Maroon |

| 321 Stainless Steel | Turquoise |

| 347 Stainless Steel | Blue |

| Monel 400 | Orange |

| Nickel 200 | Red |

| Titanium | Purple |

| 20Cb-3 Alloy | Black |

| Hastelloy B | Brown |

| Hastelloy C | Beige |

| Inconel 600 | Gold |

| Incoloy 800 | White |

| Per ASME B16.20-2007 | |

| Nonmetallic Filler Materials | Color Code |

| Polytetrafluoroethylene | White Stripe |

| Mica-Graphite | Pink Stripe |

| Flexible Graphite | Gray Stripe |

| Ceramic | Light Green Stripe |

Governing Standards

| ASME B16.20 | Covers metal ring-joint gaskets, spiral-wound gaskets, metal-jacketed gaskets, and grooved metal gaskets with covering layers. |

| ASME B16.47 | Covers pressure-temperature ratings, materials, dimensions, tolerances, marking, and testing for pipe flanges in sizes NPS 26 through NPS 60. Included are flanges with rating class designations 75, 150, 300, 400, 600, and 900 with requirements given in both SI (Metric) and U. S. Customary units, with diameter of bolts and flange bolt hole expressed in inch units. |

Dimensional Specifications

| Per ASME B16.20-2017 | ||||||||||||||||||||

| Pipe Diameter | ||||||||||||||||||||

| 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | ||

| Inner Ring ID per Class |

150# | 0.56 | 0.81 | 1.06 | 1.50 | 1.75 | 2.19 | 2.62 | 3.19 | 4.19 | 5.19 | 6.19 | 8.50 | 10.56 | 12.50 | 13.75 | 15.75 | 17.69 | 19.69 | 23.75 |

| 300# | 0.56 | 0.81 | 1.06 | 1.50 | 1.75 | 2.19 | 2.62 | 3.19 | 4.19 | 5.19 | 6.19 | 8.50 | 10.56 | 12.50 | 13.75 | 15.75 | 17.69 | 19.69 | 23.75 | |

| 600# | 0.56 | 0.81 | 1.06 | 1.50 | 1.75 | 2.19 | 2.62 | 3.19 | 4.04 | 5.05 | 6.10 | 8.10 | 10.05 | 12.10 | 13.50 | 15.35 | 17.25 | 19.25 | 23.25 | |

| 900# | 0.56 | 0.81 | 1.06 | 1.31 | 1.63 | 2.06 | 2.50 | 3.10 | 4.05 | 5.05 | 6.10 | 7.75 | 9.69 | 11.50 | 12.63 | 14.75 | 16.75 | 19.00 | 23.25 | |

| 1500# | 0.56 | 0.81 | 1.06 | 1.31 | 1.63 | 2.06 | 2.50 | 3.10 | 3.85 | 4.90 | 5.80 | 7.75 | 9.69 | 11.50 | 12.63 | 14.50 | 16.75 | 18.75 | 22.75 | |

| 2500# | 0.56 | 0.81 | 1.06 | 1.31 | 1.63 | 2.06 | 2.50 | 3.10 | 3.85 | 4.90 | 5.80 | 7.75 | 9.69 | 11.50 | ||||||

| Winding ID per Class |

150# | 0.75 | 1.00 | 1.25 | 1.88 | 2.13 | 2.75 | 3.25 | 4.00 | 5.00 | 6.13 | 7.19 | 9.19 | 11.31 | 13.38 | 14.63 | 16.63 | 18.69 | 20.69 | 24.75 |

| 300# | 0.75 | 1.00 | 1.25 | 1.88 | 2.13 | 2.75 | 3.25 | 4.00 | 5.00 | 6.13 | 7.19 | 9.19 | 11.31 | 13.38 | 14.63 | 16.63 | 18.69 | 20.69 | 24.75 | |

| 600# | 0.75 | 1.00 | 1.25 | 1.88 | 2.13 | 2.75 | 3.25 | 4.00 | 4.75 | 5.81 | 6.88 | 8.88 | 10.81 | 12.88 | 14.25 | 16.25 | 18.50 | 20.50 | 24.75 | |

| 900# | 0.75 | 1.00 | 1.25 | 1.56 | 1.80 | 2.31 | 2.75 | 3.75 | 4.75 | 5.81 | 6.88 | 8.75 | 10.88 | 12.75 | 14.00 | 16.25 | 18.25 | 20.50 | 24.75 | |

| 1500# | 0.75 | 1.00 | 1.25 | 1.56 | 1.80 | 2.31 | 2.75 | 3.63 | 4.63 | 5.63 | 6.75 | 8.50 | 10.50 | 12.75 | 14.00 | 16.00 | 18.25 | 20.25 | 25.25 | |

| 2500# | 0.75 | 1.00 | 1.25 | 1.56 | 1.88 | 2.31 | 2.75 | 3.63 | 4.63 | 5.63 | 6.75 | 8.50 | 10.93 | 12.50 | ||||||

| Winding OD per Class |

150# | 1.25 | 1.56 | 1.88 | 2.38 | 2.75 | 3.38 | 3.88 | 4.75 | 5.88 | 7.00 | 8.25 | 10.38 | 12.50 | 14.75 | 16.00 | 18.25 | 20.75 | 22.75 | 27.00 |

| 300# | 1.25 | 1.56 | 1.88 | 2.38 | 2.75 | 3.38 | 3.88 | 4.75 | 5.88 | 7.00 | 8.25 | 10.38 | 12.50 | 14.75 | 16.00 | 18.25 | 20.75 | 22.75 | 27.00 | |

| 600# | 1.25 | 1.56 | 1.88 | 2.38 | 2.75 | 3.38 | 3.88 | 4.75 | 5.88 | 7.00 | 8.25 | 10.38 | 12.50 | 14.75 | 16.00 | 18.25 | 20.75 | 22.75 | 27.00 | |

| 900# | 1.25 | 1.56 | 1.88 | 2.38 | 2.75 | 3.38 | 3.88 | 4.75 | 5.88 | 7.00 | 8.25 | 10.13 | 12.25 | 14.50 | 15.75 | 18.00 | 22.50 | 22.50 | 26.75 | |

| 1500# | 1.25 | 1.56 | 1.88 | 2.38 | 2.75 | 3.38 | 3.88 | 4.75 | 5.88 | 7.00 | 8.25 | 10.13 | 12.25 | 14.50 | 15.75 | 18.00 | 22.50 | 22.50 | 26.75 | |

| 2500# | 1.25 | 1.56 | 1.88 | 2.38 | 2.75 | 3.38 | 3.88 | 4.75 | 5.88 | 7.00 | 8.25 | 10.13 | 12.25 | 14.50 | ||||||

| Outer Ring OD per Class |

150# | 1.88 | 2.25 | 2.63 | 3.00 | 3.38 | 4.13 | 4.88 | 5.38 | 6.88 | 7.75 | 8.75 | 11.00 | 13.38 | 16.13 | 17.75 | 20.25 | 21.63 | 23.88 | 28.25 |

| 300# | 2.13 | 2.50 | 2.88 | 3.25 | 3.75 | 4.38 | 5.13 | 5.88 | 7.13 | 8.50 | 9.88 | 12.13 | 14.25 | 16.63 | 19.13 | 21.25 | 23.50 | 25.75 | 30.50 | |

| 600# | 2.13 | 2.50 | 2.88 | 3.25 | 3.75 | 4.38 | 5.13 | 5.88 | 7.63 | 9.50 | 10.50 | 12.63 | 15.75 | 18.00 | 19.38 | 22.25 | 24.13 | 26.88 | 31.13 | |

| 900# | 2.50 | 2.75 | 3.13 | 3.50 | 3.88 | 5.63 | 6.50 | 6.63 | 8.13 | 9.75 | 11.38 | 14.13 | 17.13 | 19.63 | 20.50 | 22.63 | 25.13 | 27.50 | 33.00 | |

| 1500# | 2.50 | 2.75 | 3.13 | 3.50 | 3.88 | 5.63 | 6.50 | 6.88 | 8.25 | 10.00 | 11.13 | 13.88 | 17.13 | 20.50 | 22.75 | 25.25 | 27.75 | 29.75 | 35.50 | |

| 2500# | 2.75 | 2.25 | 3.38 | 4.13 | 4.63 | 5.75 | 6.63 | 7.75 | 9.25 | 11.00 | 12.50 | 15.25 | 18.75 | 21.63 | ||||||

| Per ASME B16.47-2017 | |||||||||||||||||||

| Series A | Pipe Diameter | ||||||||||||||||||

| 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 58 | 60 | ||

| Inner Ring ID per Class |

150# | 25.75 | 27.75 | 29.75 | 31.75 | 33.75 | 35.75 | 37.75 | 39.75 | 41.75 | 43.75 | 45.75 | 47.75 | 49.75 | 51.75 | 53.50 | 55.50 | 57.50 | 59.50 |

| 300# | 25.75 | 27.75 | 29.75 | 31.75 | 33.75 | 35.75 | 37.50 | 39.50 | 41.50 | 43.50 | 45.38 | 47.63 | 49.00 | 52.00 | 53.25 | 55.25 | 57.00 | 60.00 | |

| 600# | 25.50 | 27.50 | 29.75 | 32.00 | 34.00 | 36.13 | 37.50 | 39.75 | 42.00 | 43.75 | 45.75 | 48.00 | 50.00 | 52.00 | 54.25 | 56.25 | 58.00 | 60.25 | |

| 900# | 26.00 | 28.00 | 30.25 | 32.00 | 34.00 | 36.25 | 39.75 | 41.75 | 43.75 | 45.50 | 48.00 | 50.00 | |||||||

| Winding ID per Class |

150# | 26.50 | 28.50 | 30.50 | 32.50 | 34.50 | 36.50 | 38.50 | 40.50 | 42.50 | 44.50 | 46.50 | 48.50 | 50.50 | 52.50 | 54.50 | 56.50 | 58.50 | 60.50 |

| 300# | 27.00 | 29.00 | 31.25 | 33.50 | 35.50 | 37.63 | 38.50 | 40.25 | 42.25 | 44.50 | 46.38 | 48.63 | 51.00 | 53.00 | 55.25 | 57.25 | 59.50 | 61.50 | |

| 600# | 27.00 | 29.00 | 31.25 | 33.50 | 35.50 | 37.63 | 39.00 | 41.25 | 43.50 | 45.75 | 47.75 | 50.00 | 52.00 | 54.00 | 56.25 | 58.25 | 60.50 | 62.75 | |

| 900# | 27.00 | 29.00 | 31.25 | 33.50 | 35.50 | 37.75 | 40.75 | 43.25 | 45.25 | 47.50 | 50.00 | 52.00 | |||||||

| Winding OD per Class |

150# | 27.75 | 29.75 | 31.75 | 33.88 | 35.88 | 38.13 | 40.13 | 42.13 | 44.25 | 46.38 | 48.38 | 50.38 | 52.50 | 54.50 | 56.50 | 58.50 | 60.50 | 62.50 |

| 300# | 29.00 | 31.00 | 33.25 | 35.50 | 37.50 | 39.63 | 40.00 | 42.13 | 44.13 | 46.50 | 48.38 | 50.63 | 53.00 | 55.00 | 57.25 | 59.25 | 61.50 | 63.50 | |

| 600# | 29.00 | 31.00 | 33.25 | 35.50 | 37.50 | 39.63 | 41.00 | 43.25 | 45.50 | 47.75 | 49.75 | 52.00 | 54.00 | 56.00 | 58.25 | 60.25 | 62.50 | 64.75 | |

| 900# | 29.00 | 31.00 | 33.25 | 35.50 | 37.50 | 39.75 | 42.75 | 45.25 | 47.25 | 49.50 | 52.00 | 54.00 | |||||||

| Outer Ring OD per Class |

150# | 30.50 | 32.75 | 34.75 | 37.00 | 39.00 | 41.25 | 43.75 | 45.75 | 48.00 | 50.25 | 52.25 | 54.50 | 56.50 | 58.75 | 61.00 | 63.25 | 65.50 | 67.50 |

| 300# | 32.88 | 35.38 | 37.50 | 39.63 | 41.63 | 44.00 | 41.50 | 43.88 | 45.88 | 48.00 | 50.13 | 52.13 | 54.25 | 56.25 | 58.75 | 60.75 | 62.75 | 64.75 | |

| 600# | 34.13 | 36.00 | 38.25 | 40.25 | 42.25 | 44.50 | 43.50 | 45.50 | 48.00 | 50.00 | 52.25 | 54.75 | 57.00 | 59.00 | 61.25 | 63.50 | 65.50 | 68.25 | |

| 900# | 34.75 | 37.25 | 39.75 | 42.25 | 44.75 | 47.25 | 47.25 | 49.25 | 51.25 | 53.88 | 56.50 | 58.50 | |||||||

| Per ASME B16.47-2017 | |||||||||||||||||||

| Series B | Pipe Diameter | ||||||||||||||||||

| 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 58 | 60 | ||

| Inner Ring ID per Class |

150# | 25.75 | 27.75 | 29.75 | 31.75 | 33.75 | 35.75 | 37.75 | 39.75 | 41.75 | 43.75 | 45.75 | 47.75 | 49.75 | 51.75 | 53.75 | 56.00 | 58.19 | 60.44 |

| 300# | 25.75 | 27.75 | 29.75 | 31.75 | 33.75 | 35.75 | 38.25 | 40.25 | 42

Loading product details...

| ||||||||||