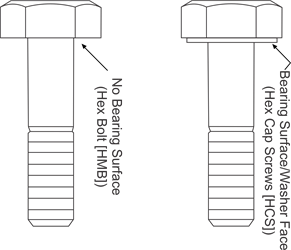

Hex Bolts vs. Hex Cap Screws

Knowing the Difference

Hex cap screws and hex bolts are two of the most commonly used fasteners in industrial and construction applications. While these fasteners are often used interchangeably, there are key differences in their design, specifications, manufacturing standards, and recommended applications. Understanding these differences will help you choose the right fastener for your specific job.

In most cases, the choice between a hex bolt and a hex cap screw isn't one you'll actively make. The decision is typically driven by factors such as material grade, thread specifications, and commercial availability. Fortunately, for the vast majority of applications, hex bolts and hex cap screws can be used interchangeably without any functional difference. While there are technical distinctions between the two—such as differences in manufacturing tolerances and threading—their performance in standard fastening applications is largely equivalent.