TENSION CONTROL BOLTS

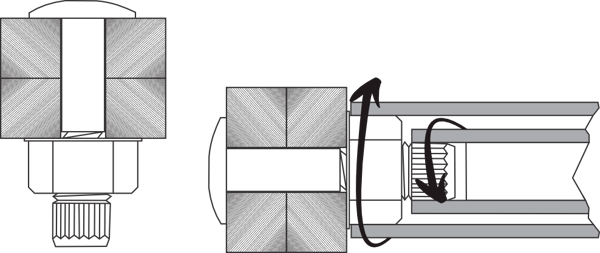

Tension control bolts (TC bolt) is a specialized type of structural bolt used in steel frame construction and other high-strength fastening applications. TC bolts are typically a pre-assembled set of a bolt, nut, and washer. They have a rounded or domed head and a partially threaded shank. The primary purpose of TC bolts is to ensure consistent and accurate tensioning in structural steel connections. This precision is essential for ensuring the integrity and safety of structures, especially in critical applications like bridges and buildings. By eliminating the guesswork associated with traditional bolt tightening methods, TC bolts help prevent under-tightening or over-tightening, which can lead to connection failures.

| |

Inch |

Metric |

Inch |

Metric |

| |

120 ksi Min Tensile |

830 MPa Min Tensile |

150 ksi Min Tensile |

1040 MPa Min Tensile |

| |

Type 1 |

Type 3 |

Type 1 |

Type 3 |

Type 1 |

Type 3 |

Type 1 |

Type 3 |

| Style - Twist-Off Bolts |

|

|

|

|

|

|

|

|

| Dimensions, ASMEB |

B18.2.6 |

B18.2.6 |

F |

F |

B18.2.6 |

B18.2.6 |

F |

F |

| Thread Fit, ASMEB |

B1.1 UNC 2A |

B1.1 UNC 2A |

F |

F |

B1.1 UNC 2A |

B1.1 UNC 2A |

F |

F |

| Grade MarkingA,D |

A325TC |

A325TC |

F |

F |

A490TC |

A490TC |

F |

F |

| Alt. MarkingA,C |

A325 |

A325 |

F |

F |

A490 |

A490 |

F |

F |

| Recommended Nut and Washer |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| Plain Nut |

A563 DH |

A563 DH3 |

A563M 10S |

A563M 10S3 |

A563 DH |

A563 DH3 |

A563M 10S |

A563M 10S3 |

| Suitable AlternativeE |

DH3, D, C, C3 |

C3 |

8S, 8S3, 10S3 |

8S3 |

|

|

10S3 |

|

| Coated Nut |

A563 DH |

A563 DH3 |

A563M 10S |

A563M 10S3 |

A563 DH |

A563 DH3 |

A563M 10S |

A563M 10S3 |

| Flat, Bevel or Thick Washer if used |

F436 - 1 |

F436 - 3 |

F436M - 1 |

F436M - 3 |

F436 - 1 |

F436 - 3 |

F436M - 1 |

F436M - 3 |

B Manufactured to the latest revision at the time of manufacture, UNC for inch series and Metric Coarse (MC) for Metric Series.

C Previously used markings may be sold and used indefinitely, bolts must be manufactured to current marking requirements upon initial publication of this standard.

D Other distinguishing markings for type 3 are permitted at the manufacturers option.

F Metric dimensions and requirements for this style have not been established.