Spiral Wound Gaskets: Construction, Color Coding & More

What Are Spiral Wound Gaskets?

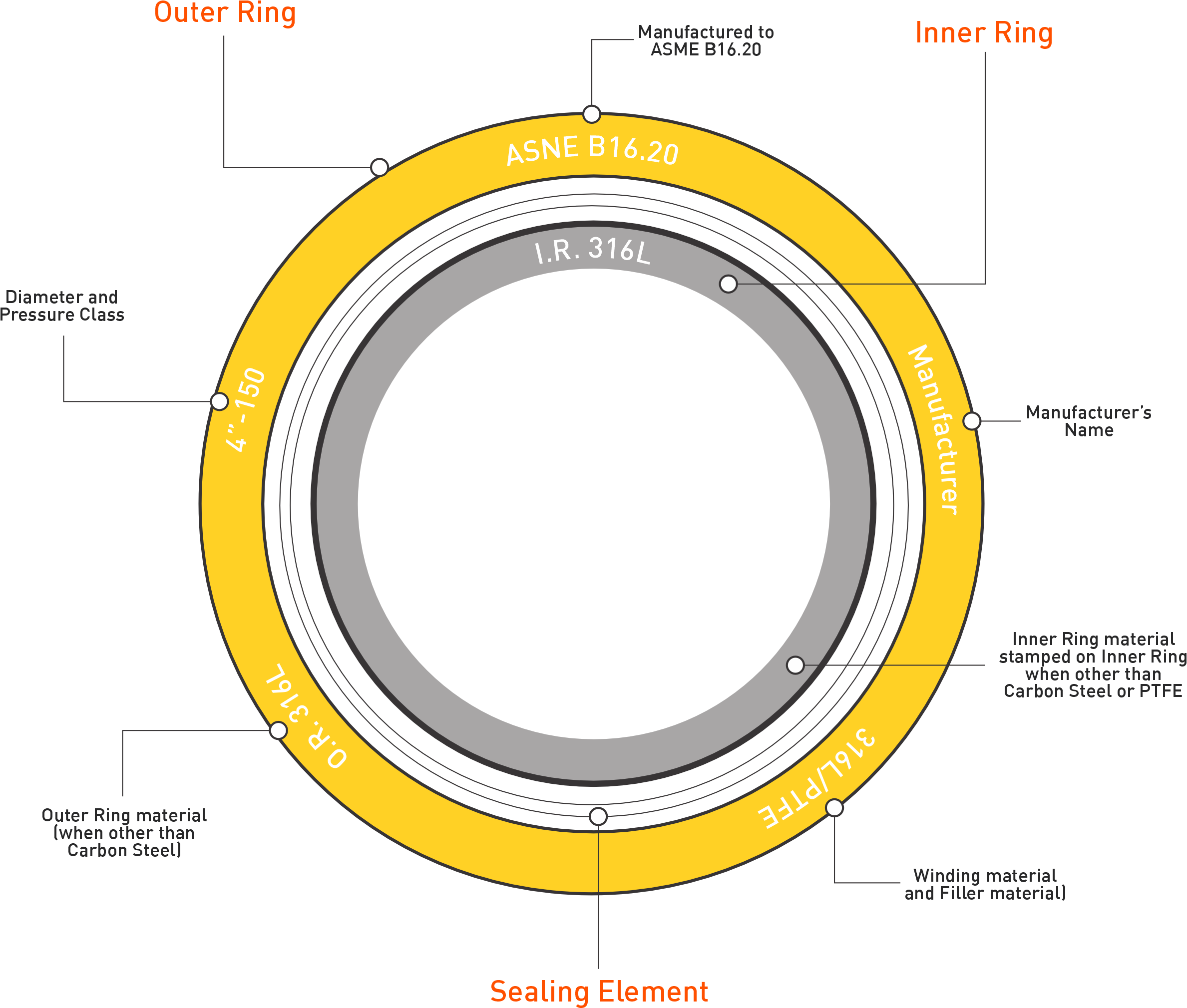

Spiral wound gaskets are engineered sealing elements designed to handle high pressures and temperatures, making them ideal for critical flange connections in pipelines, refineries, and industrial plants. They consist of a mix of metallic and non-metallic materials wound together to form a resilient gasket capable of maintaining a seal under fluctuating conditions. Many manufacturers currently fabricate their own spiral wound gaskets, with the majority specifying ASME B16.20 guidelines.