DIRECT TENSION INDICATORS (DTI'S)

What Are Direct Tension Indicators (DTI's)?

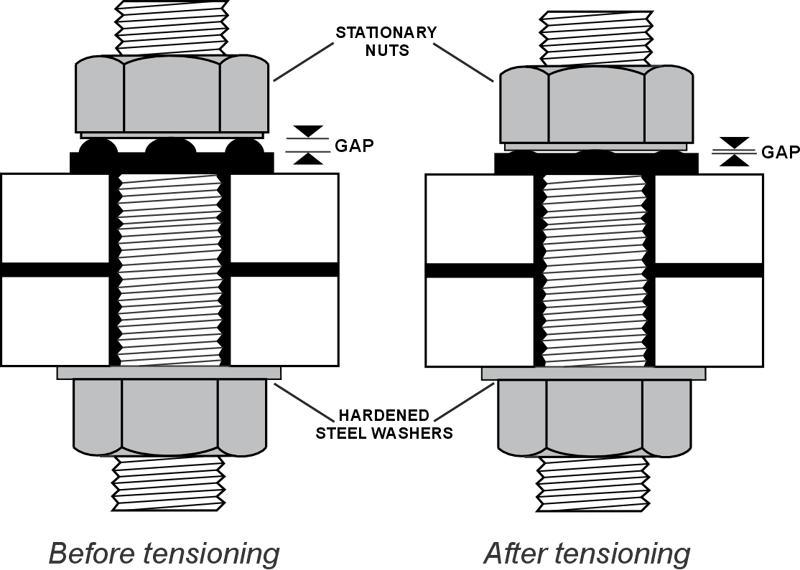

Direct Tension Indicators (DTIs) are specialized washers used in structural bolting assemblies to visually confirm that proper bolt tension (preload) has been achieved during installation. Commonly used in steel construction and infrastructure projects, DTIs provide an accurate, low-cost method to verify compliance with bolting specifications, such as those defined by the Research Council on Structural Connections (RCSC) and ASTM F959.

Types of DTI Washers

Direct Tension Indicators come in several configurations to accommodate different installation conditions, inspection preferences, and coating requirements. Below is a breakdown of the most commonly used DTI types: