Tapping Internal Threads

The Importance of Choosing the Right Tap

For precision cutting, choosing the right tool is essential. Taps, which are used to create internal threads on a workpiece, provide accuracy, customization, and cost-efficiency across a wide range of machining and manufacturing tasks. With the right tap, threads are formed with precision, ensuring excellent engagement, durability, and wear resistance. Taps come in a variety of materials, coatings, flute designs, lengths, and other specifications. To help you select the ideal tap for your needs, the following provides an overview of each specification, ensuring optimal efficiency and productivity.

Order HSS Taps Order Nitro Spiral Point Taps Order Nitro Spiral Flute Taps

Determining the Application

Hand tapping requires manual control and is best-suited for low-volume or delicate tasks where feel and on-the-fly adjustments are crucial. This method offers flexibility in tight or hard-to-reach spaces but is a slower, manual process.

Machine tapping, executed with a drill press or tapping machine, with specialized designs to efficiently handle chips, is ideal for high-speed, consistent threading in high volume, offering greater precision and uniformity while reducing operator fatigue and effortlessly handling tougher materials.

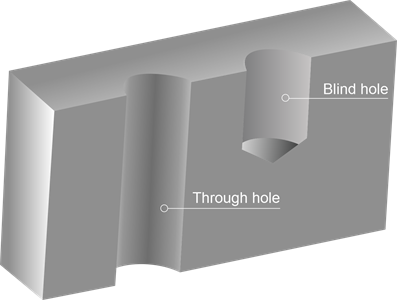

Determining the Type of Hole

When choosing what taps are right for you, you will need to consider the type of hole you're trying to make; whether you'll be hand or machine tapping, and the materials on which you'll be working.

• A blind hole does not go all the way through the material.

• A through hole goes completely through the material.

Tap Geometries

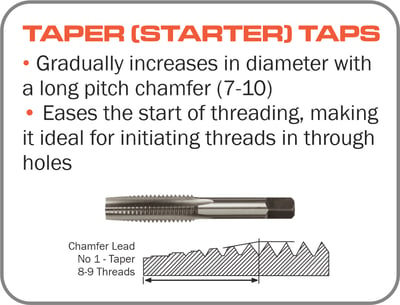

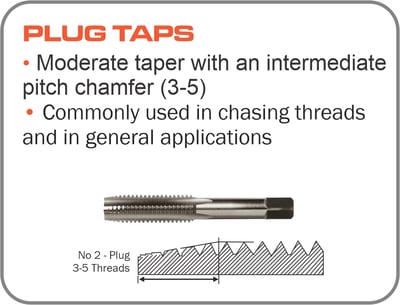

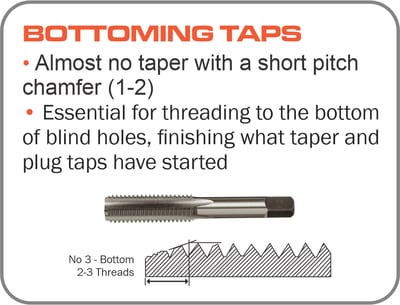

For Hand Tapping of Through and Blind Holes

For Machine Tapping of Through and Blind Holes

Tapered Taps for Threading Pipe

Choosing the Right Taps

| Hand Taps | Spiral Point Taps | Spiral Flute Taps | Pipe Taps | |

| Application | Wrench (manual) | Machine | Machine | For tapping into pipes and fittings |

| Description | Hand taps have 3 standard chamfer geometries including taper, plug, and bottoming. They have straight flutes and are the most popular and versatile styles of taps in general machine tapping operations. |

An additional grind on the tip of the tap propels the chips ahead causing less load and clogging in the flutes. The combination of forward chip ejection and reduced cutting torque allows for faster and more efficient tapping in through hole applications |

The design of spiral flute taps is conducive to improved chip flow. The flutes pull the chips out of the workpiece, which reduces the changes of tap breakage in blind hole applications. Featuring helical flutes that propel the chips upward and allows for better coolant flow to the cutting area, helping to dissipate heat and prolong tool life. |

Pipe taps are specialized tools used for tapping NPT pipe threads to mate with threaded pipe and fittings that conform to standard pipe sizes and provide tight, leak-proof connections. |

| Chip Removal | Manual chip breakage | Chips break automatically - Evacuates chips down |

Chips break automatically - Pulls chips out |

Manual chip breakage |

| Type of Hole | Through (for Taper and Plug), Blind (for Taper, Plug and Bottoming) |

Blind for Plug | Blind for Bottoming | Through for Plug |

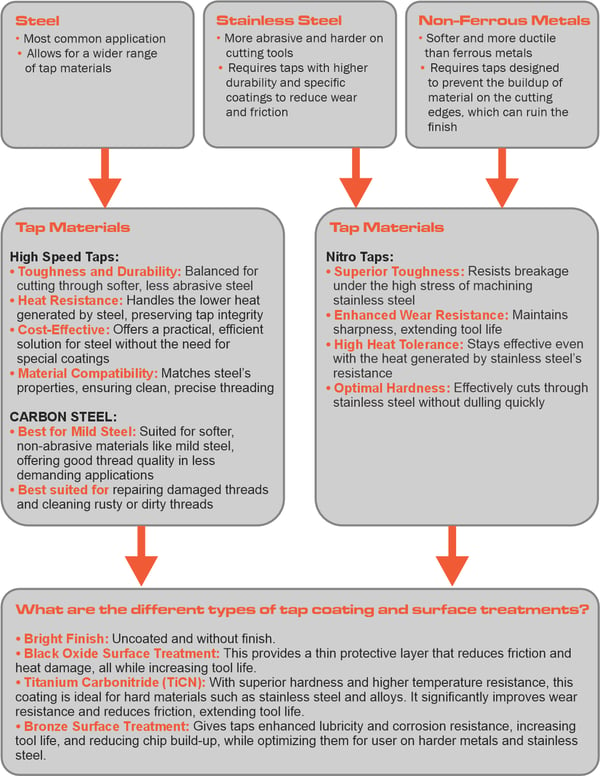

Selecting the Tap Based on the Material

The next step is assessing the material you'll be working on. Once you know the material, you'll be able to match it with the appropriate tap material and coating.

Drill Size Decimal Equivalent Chart

| Drill Size | Decimal Equivalent | mm | Drill Size | Decimal Equivalent | mm | Drill Size | Decimal Equivalent | mm |

| 80 | 0.0135 | 0.343 | 31 | 0.12 | 3.048 | 5/16 | 0.3125 | 7.938 |

| 79 | 0.0145 | 0.368 | 1/8 | 0.125 | 3.175 | O | 0.316 | 8.026 |

| 1/64 | 0.0156 | 0.396 | 30 | 0.1285 | 3.264 | P | 0.323 | 8.204 |

| 78 | 0.016 | 0.406 | 29 | 0.136 | 3.454 | 21/64 | 0.3281 | 8.334 |

| 77 | 0.018 | 0.457 | 28 | 0.1405 | 3.569 | Q | 0.332 | 8.433 |

| 76 | 0.02 | 0.508 | 9/64 | 0.1406 | 3.571 | R | 0.339 | 8.611 |

| 75 | 0.021 | 0.533 | 27 | 0.144 | 3.658 | 11/32 | 0.3438 | 8.733 |

| 74 | 0.0225 | 0.572 | 26 | 0.147 | 3.734 | S | 0.348 | 8.839 |

| 73 | 0.024 | 0.610 | 25 | 0.1495 | 3.797 | T | 0.358 | 9.093 |

| 72 | 0.025 | 0.635 | 24 | 0.152 | 3.861 | 23/64 | 0.3594 | 9.129 |

| 71 | 0.026 | 0.660 | 23 | 0.154 | 3.912 | U | 0.368 | 9.347 |

| 70 | 0.028 | 0.711 | 5/32 | 0.15625 | 3.969 | 3/8 | 0.375 | 9.525 |

| 69 | 0.0292 | 0.742 | 22 | 0.157 | 3.988 | V | 0.377 | 9.576 |

| 68 | 0.031 | 0.787 | 21 | 0.159 | 4.039 | W | 0.386 | 9.804 |

| 1/32 | 0.03125 | 0.794 | 20 | 0.161 | 4.089 | 25/64 | 0.3906 | 9.921 |

| 67 | 0.032 | 0.813 | 19 | 0.166 | 4.216 | X | 0.397 | 10.084 |

| 66 | 0.033 | 0.838 | 18 | 0.1695 | 4.305 | Y | 0.404 | 10.262 |

| 65 | 0.035 | 0.889 | 11/64 | 0.1719 | 4.366 | 13/32 | 0.40625 | 10.319 |

| 64 | 0.036 | 0.914 | 17 | 0.173 | 4.394 | Z | 0.413 | 10.490 |

| 63 | 0.037 | 0.940 | 16 | 0.177 | 4.496 | 27/64 | 0.4219 | 10.716 |

| 62 | 0.038 | 0.965 | 15 | 0.18 | 4.572 | 7/16 | 0.4375 | 11.113 |

| 61 | 0.039 | 0.991 | 14 | 0.182 | 4.623 | 29/64 | 0.4531 | 11.509 |

| 60 | 0.04 | 1.016 | 13 | 0.185 | 4.699 | 15/32 | 0.4688 | 11.908 |

| 59 | 0.041 | 1.041 | 3/16 | 0.1875 | 4.763 | 31/64 | 0.4844 | 12.304 |

| 58 | 0.042 | 1.067 | 12 | 0.189 | 4.801 | 1/2 | 0.5 | 12.700 |

| 57 | 0.043 | 1.092 | 11 | 0.191 | 4.851 | 33/64 | 0.5156 | 13.096 |

| 56 | 0.0465 | 1.181 | 10 | 0.1935 | 4.915 | 17/32 | 0.53125 | 13.494 |

| 3/64 | 0.0469 | 1.191 | 9 | 0.196 | 4.978 | 35/64 | 0.5469 | 13.891 |

| 55 | 0.052 | 1.321 | 8 | 0.199 | 5.055 | 9/16 | 0.5625 | 14.288 |

| 54 | 0.055 | 1.397 | 7 | 0.201 | 5.105 | 37/64 | 0.5781 | 14.684 |

| 53 | 0.0595 | 1.511 | 13/64 | 0.2031 | 5.159 | 19/32 | 0.5938 | 15.083 |

| 1/16 | 0.0625 | 1.588 | 6 | 0.204 | 5.182 | 39/64 | 0.6094 | 15.479 |

| 52 | 0.0635 | 1.613 | 5 | 0.2055 | 5.220 | 5/8 | 0.625 | 15.875 |

| 51 | 0.067 | 1.702 | 4 | 0.209 | 5.309 | 41/64 | 0.6406 | 16.271 |

| 50 | 0.07 | 1.778 | 3 | 0.213 | 5.410 | 21/32 | 0.65625 | 16.669 |

| 49 | 0.073 | 1.854 | 7/32 | 0.2188 | 5.558 | 43/64 | 0.6719 | 17.066 |

| 48 | 0.076 | 1.930 | 2 | 0.221 | 5.613 | 11/16 | 0.6875 | 17.463 |

| 5/64 | 0.0781 | 1.984 | 1 | 0.228 | 5.791 | 45/64 | 0.7031 | 17.859 |

| 47 | 0.0785 | 1.994 | A | 0.234 | 5.944 | 23/32 | 0.7188 | 18.258 |

| 46 | 0.081 | 2.057 | 15/64 | 0.2344 | 5.954 | 47/64 | 0.7344 | 18.654 |

| 45 | 0.082 | 2.083 | B | 0.238 | 6.045 | 3/4 | 0.75 | 19.050 |

| 44 | 0.086 | 2.184 | C | 0.242 | 6.147 | 49/64 | 0.7656 | 19.446 |

| 43 | 0.089 | 2.261 | D | 0.246 | 6.248 | 25/32 | 0.78125 | 19.844 |

| 42 | 0.0935 | 2.375 | 1/4 (E) | 0.25 | 6.350 | 51/64 | 0.7969 | 20.241 |

| 3/32 | 0.0938 | 2.383 | F | 0.257 | 6.528 | 13/16 | 0.8125 | 20.638 |

| 41 | 0.096 | 2.438 | G | 0.261 | 6.629 | 53/64 | 0.8281 | 21.034 |

| 40 | 0.098 | 2.489 | 17/64 | 0.2656 | 6.746 | 27/32 | 0.8438 | 21.433 |

| 39 | 0.0995 | 2.527 | H | 0.266 | 6.756 | 55/64 | 0.8594 | 21.829 |

| 38 | 0.1015 | 2.578 | I | 0.272 | 6.909 | 7/8 | 0.875 | 22.225 |

| 37 | 0.104 | 2.642 | J | 0.277 | 7.036 | 57/64 | 0.8906 | 22.621 |

| 36 | 0.1065 | 2.705 | K | 0.281 | 7.137 | 29/32 | 0.90625 | 23.019 |

| 7/64 | 0.1094 | 2.779 | 9/32 | 0.28125 | 7.144 | 59/64 | 0.9219 | 23.416 |

| 35 | 0.11 | 2.794 | L | 0.29 | 7.366 | 15/16 | 0.9375 | 23.813 |

| 34 | 0.111 | 2.819 | M | 0.295 | 7.493 | 61/64 | 0.9531 | 24.209 |

| 33 | 0.113 | 2.870 | 19/64 | 0.2969 | 7.541 | 31/32 | 0.9688 | 24.608 |

| 32 | 0.116 | 2.946 | N | 0.302 | 7.671 | 63/64 | 0.9844 | 25.004 |

Tap Drill Size Chart

| Tap Size | Drill Size | Probable % Thread |

| M3-0.5 | 40 | 70-79 |

| 5-40 | 38 | 65-72 |

| 5-44 | 37 | 63-71 |

| M3.5-0.6 | 33 | 72-81 |

| 6-32 | 36 | 71-78 |

| 6-40 | 33 | 69-77 |

| M4-0.7 | 3.25 mm | 74-82 |

| 8-32 | 29 | 62-69 |

| 8-36 | 29 | 70-78 |

| 10-24 | 25 | 69-75 |

| 10-32 | 21 | 68-76 |

| M5-0.8 | 4.2 mm | 69-77 |

| 12-24 | 16 | 66-72 |

| 12-28 | 15 | 70-78 |

| M6-1.0 | 10 | 76-84 |

| 1/4-20 | 7 | 70-75 |

| 1/4-28 | 3 | 72-80 |

| 5/16-18 | F | 72-77 |

| 5/16-24 | I | 67-75 |

| M8-1.25 | 6.7 mm | 74-80 |

| 3/8-16 | 5/16 | 72-77 |

| 3/8-24 | Q | 71-79 |

| M10-1.50 | 8.4 mm | 76-82 |

| 7/16-14 | U | 70-75 |

| 7/16-20 | 25/64 | 65-72 |

| M12-1.75 | 13/32 | 69-74 |

| 1/2-13 | 27/64 | 73-78 |

| 1/2-20 | 29/64 | 65-72 |

| M14-2.0 | 15/32 | 76-81 |

| 9/16-12 | 31/64 | 68-72 |

| 9/16-18 | 33/64 | 58-65 |

| 5/8-11 | 17/32 | 75-79 |

| 5/8-18 | 37/64 | 58-65 |

| M16-2.0 | 35/64 | 76-81 |

| 3/4-10 | 21/32 | 68-72 |

| 3/4-16 | 11/16 | 71-77 |

| M20-2.5 | 11/16 | 74-78 |

| 7/8-9 | 49/64 | 72-76 |

| 7/8-14 | 13/16 | 62-67 |

| M24-3.0 | 53/64 | 72-76 |

| 1-8 | 7/8 | 73-77 |

| 1-12 | 59/64 | 67-72 |

| 1-14 | 15/16 | 61-67 |

| 1-1/8-7 | 63/64 | 72-76 |

| 1-1/8-8 | 1 | 76 |

| 1-1/8-12 | 1-3/16 | 66-72 |

| M30-3.5 | 1-3/64 | 75 |

| 1-1/4-7 | 1-7/64 | 76 |

| 1-1/4-8 | 1-1/8 | 76 |

| 1-1/4-12 | 1-11/64 | 72 |

| 1-3/8-6 | 1-7/32 | 72 |

| 1-3/8-12 | 1-19/64 | 72 |

| M36-4.0 | 1-1/4 | 82 |

| 1-1/2-6 | 1-11/32 | 72 |

| 1-1/2-8 | 1-3/8 | 76 |

| 1-1/2-12 | 1-27/64 | 72 |

| NPT Tap Size | Taper Pipe Drill Size | Straight Pipe Drill Size |

| 1/8-27 | R | 11/32 |

| 1/4-18 | 7/16 | 7/16 |

| 3/8-18 | 37/64 | 37/64 |

| 1/2-14 | 45/64 | 23/32 |

| 3/4-14 | 59/64 | 59/64 |

| 1-11.5 | 1-5/32 | 1-5/32 |

| 1-1/4-11.5 | 1-1/2 | 1-1/2 |

| 1-1/2-11.5 | 1-47/64 | 1-3/4 |

| 2-11.5 | 2-7/32 | 2-7/32 |