Chemical Requirements

| Grade 36 |

Grades 55 and 105 |

||

| Element |

Diameters up to 3/4, incl. |

Over 7/8 to 4, incl. |

All Diameters |

| Carbon, max, % | |||

| Heat | 0.25 | 0.25 | |

| Product | 0.28 | 0.28 | |

| Manganese, % | |||

| Heat | 0.60-0.90 | ||

| Product | 0.54-0.98 | ||

| Phosphorus, max, % | |||

| Heat | 0.04 | 0.04 | 0.04 |

| Product | 0.05 | 0.05 | 0.048† |

| Sulfur, max, % | |||

| Heat | 0.05 | 0.05 | 0.05 |

| Product | 0.06 | 0.06 | 0.058† |

| Copper, min, % | |||

| (when specified) | |||

| Heat | 0.20 | 0.20 | 0.20 |

| Product | 0.18 | 0.18 | 0.18 |

†Editorially corrected in April 2016.

Classification

| Description | |||

| Grade | Tensile Strength, ksi (MPa) |

Yield Strength, min, ksi (MPa) |

Diameter Range, in. |

| 36 | 58-80 (400-558) | 36 (248) | 1/2 - 4 |

| 55 | 75-95 (517-655) | 55 (380) | 1/2 - 4 |

| 105 | 125-150 (862-1034) | 105 (724) | 1/2 - 3 |

| Class | |||

| 1A | anchor bolts with Class 1A threads | ||

| 2A | anchor bolts with Class 2A threads | ||

Specification for A563 Nut

| Anchor Bolt Grade and Diameter, in. |

Plain |

Hot-Dip or Mechanical Zinc-coated in |

|||

| Grade | Diameter, in. | Grade | Style | Grade | Style |

| 36 | 1/2 - 1 1/2 over 1 1/2 |

A | Hex | A | Hex |

| A | Heavy Hex | A | Heavy Hex | ||

| 55 | 1/2 - 1 1/2 over 1 1/2 - 4 |

A | Hex | A | Heavy Hex |

| A | Heavy Hex | A | Heavy Hex | ||

| 105 | All | DH | Heavy Hex | DH | Heavy Hex |

Tensile Properties for Bars and Machined Specimens

| Grade | |||

| 36 | 55 | 105 | |

| Tensile strength, ksi | 58-80 | 75-95 | 125-150 |

| Yield strength, min, ksi (0.2 % offset) | 36 | 55 | 105 |

| Elongation in 8 in., min, %A | 20 | 18 | 12 |

| Elongation in 2 in. min, %A | 23 | 21 | 15 |

| Reduction of Area, min, % | 40 | 30 | 45 |

AElongation in 8 in. applies to bars. Elongation in 2 in. applies to machined specimens.

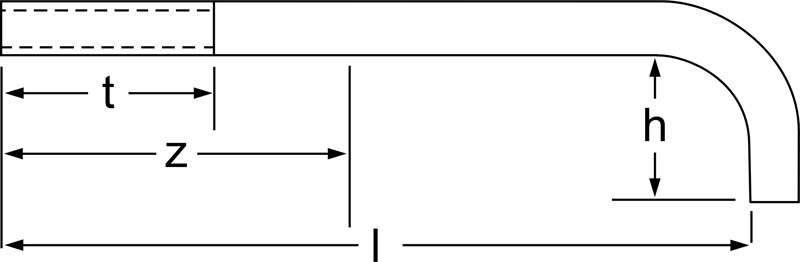

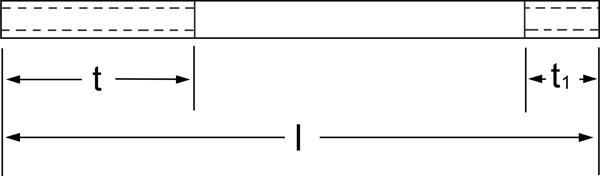

Anchor Bolt with Hook

Anchor Bolt with Hook

h = length of hook

l = length of bolt

t = length of threads (exposed end)

t1 = length of threads (encased end), when required

z = length of zinc coating, min, when partial zinc coating is required

Product Marking

| Grade | Color | |

| 36 | Blue | |

| 55 | Yellow | |

| 55 - Weldable | Yellow (projecting end) & White (encased end) |

|

| 105 | Red | |

Permanent Grade Identification

| Grade | Indentification |

| 36 | AB36 |

| 55 | AB55 |

| 105 | AB105 |