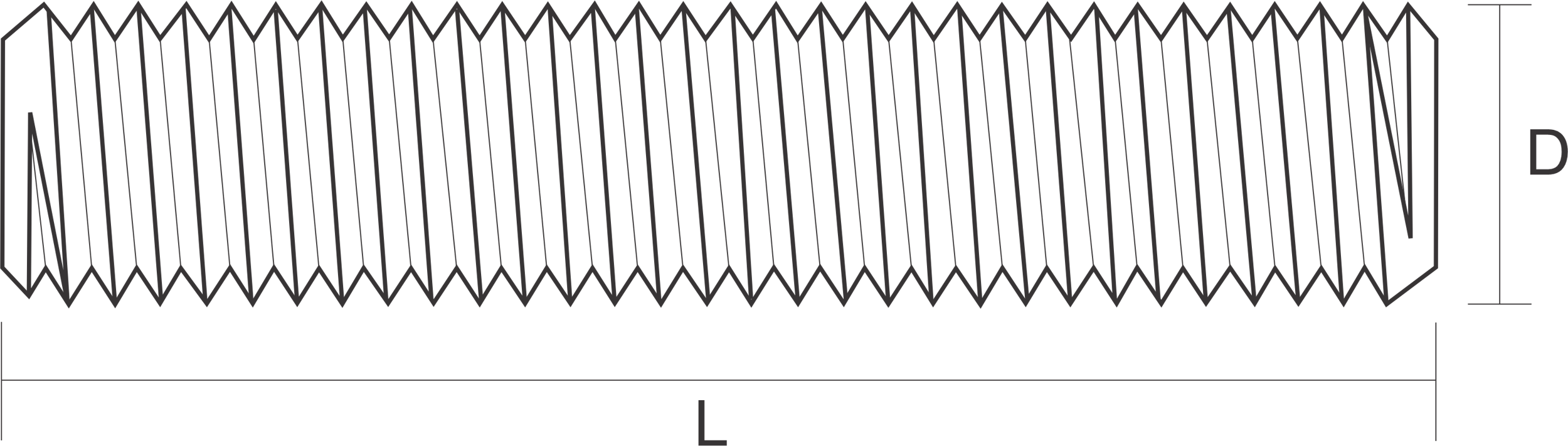

Grade 55 All Thread Rod: Specifications & Applications

ASTM F1554 Grade 55 All Thread Rod is a heat-treated, high-strength threaded fastener designed for structural and industrial applications where standard threaded rod does not provide adequate load capacity. Commonly used in anchoring, steel connections, and equipment mounting, Grade 55 offers reliable performance and improved strength for demanding service conditions.

This page serves as a practical resource covering material specifications, mechanical performance, compatible nut grades, coatings and finishes, and common applications of Grade 55 all thread rod.

Your Trusted Source for Grade 55 All Thread Rod

STS Industrial supplies Grade 55 all thread rod for structural and industrial applications where higher strength and load capacity are required. Manufactured from heat-treated carbon steel and produced to applicable industry standards, Grade 55 all thread provides reliable performance when used in anchoring, steel connection, and equipment mounting applications. Available in a range of diameters, lengths, and finishes, our team can assist with proper selection and specification support to ensure compliant, dependable performance.